OUR CLIENTS

NetYield provides seafood-specific tools and workflows across the value chain

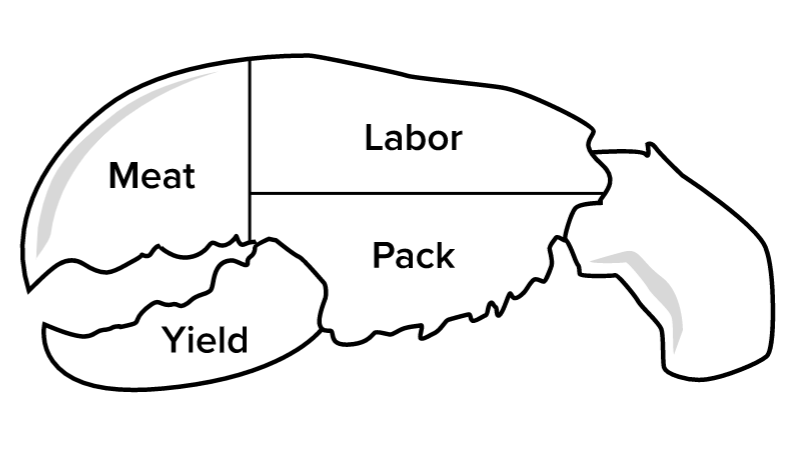

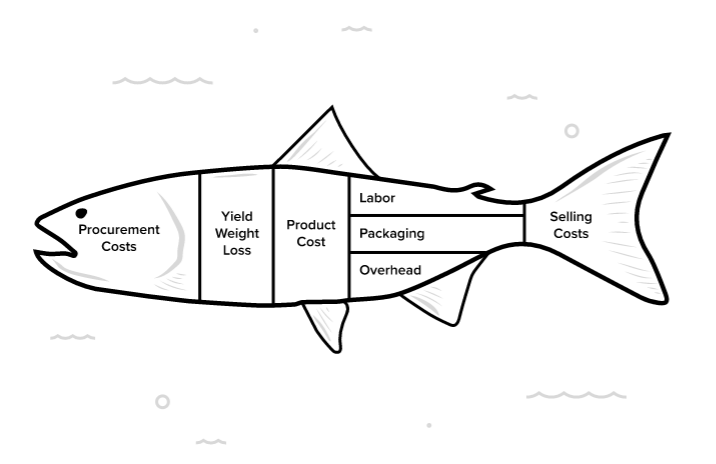

NetYield helps seafood processors build out an increasingly detailed understanding of their cost structure as they grow. We work with companies to help them put in place basic inventory control and yielding, come back to help them break out and optimize their procurement and selling costings, and finally detail out value add including labor, packaging, and overhead.

NetYield helps seafood processors build out an increasingly detailed understanding of their cost structure as they grow. We work with companies to help them put in place basic inventory control and yielding, come back to help them break out and optimize their procurement and selling costings, and finally detail out value add including labor, packaging, and overhead.

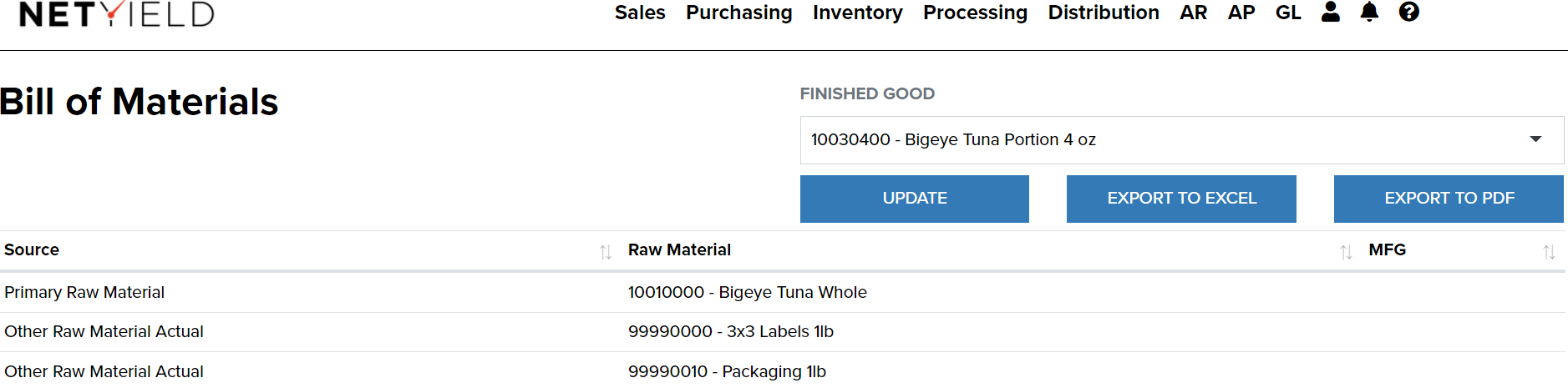

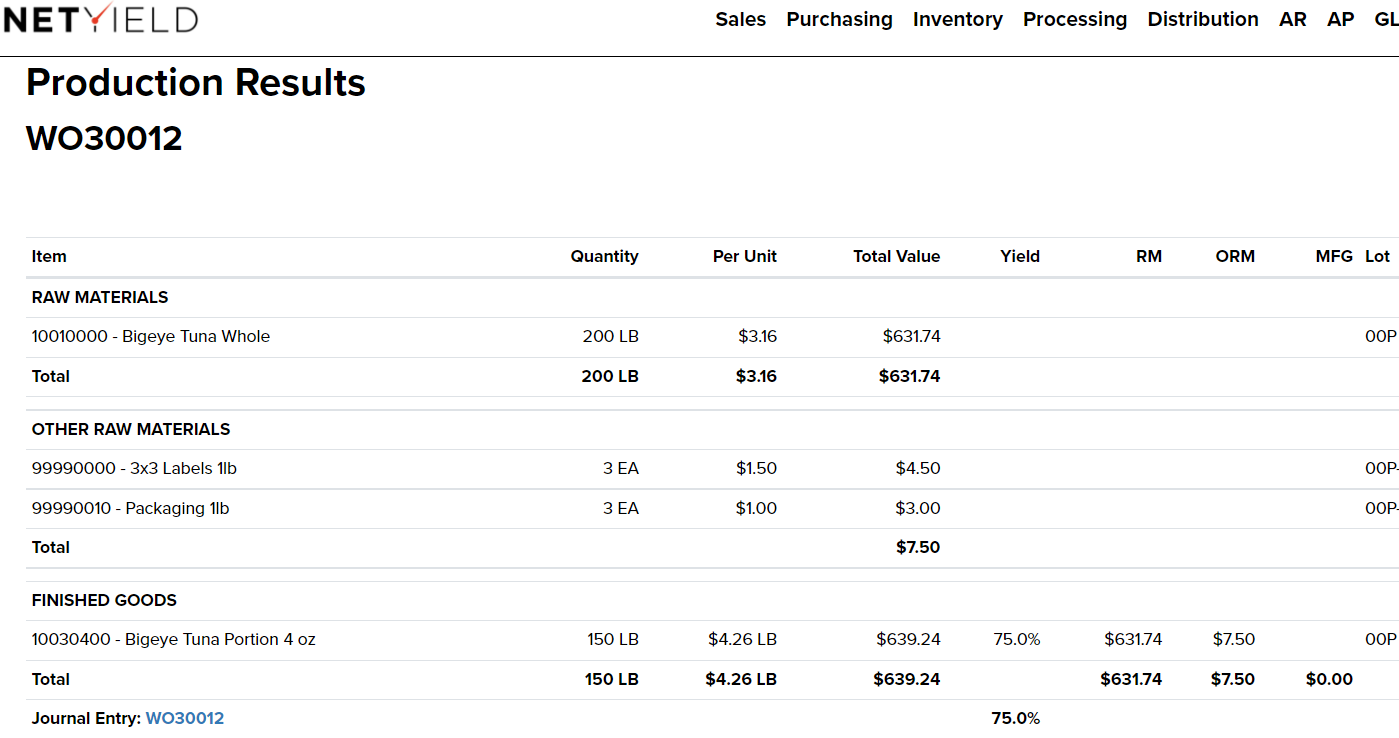

INVERTED BILL OF MATERIAL

One raw material makes many finished goods, including byproducts

OTHER RAW MATERIALS

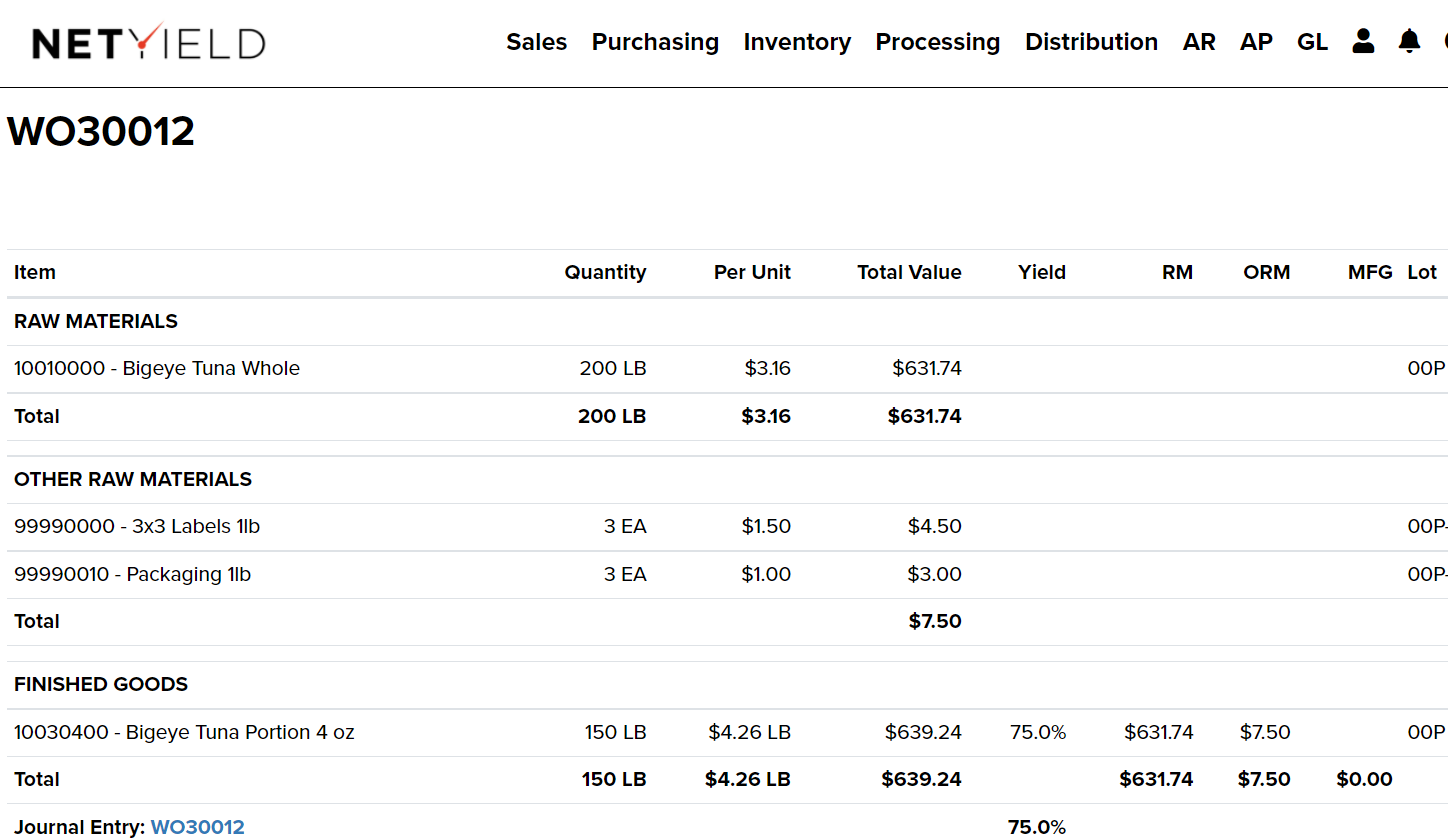

Work Order uses the primary raw material and any other raw materials required for the finished good

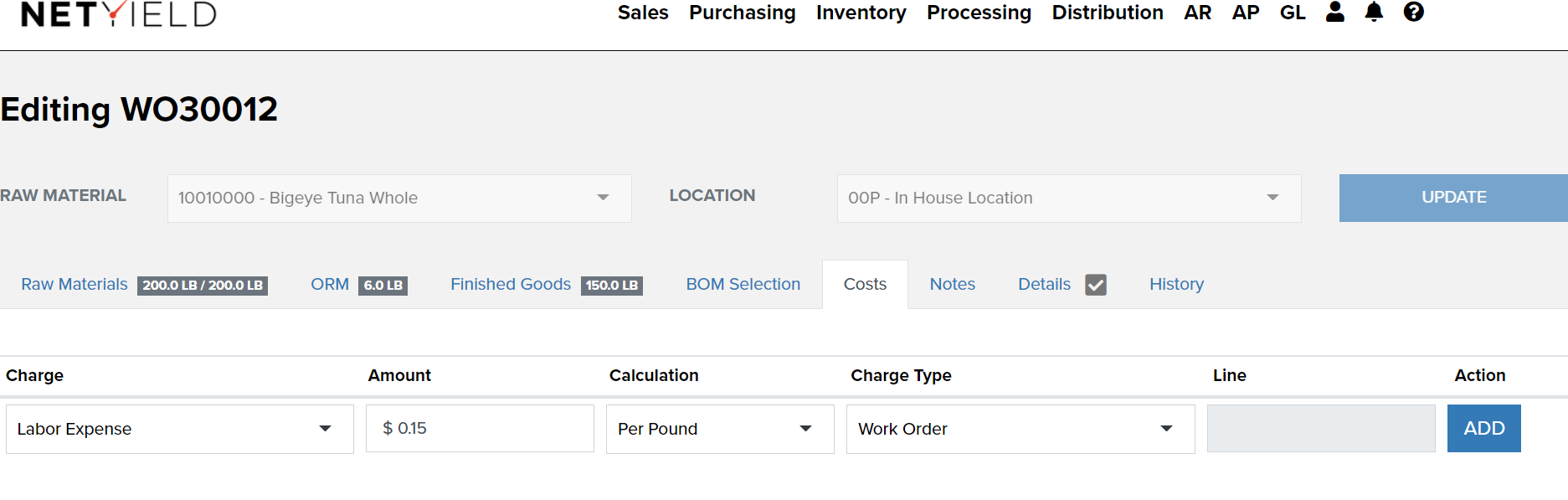

MANUFACTURING COSTS

Work Order adds any charges needed to the finished good

PRODUCTION RESULTS

Production Results shown in the Work Order

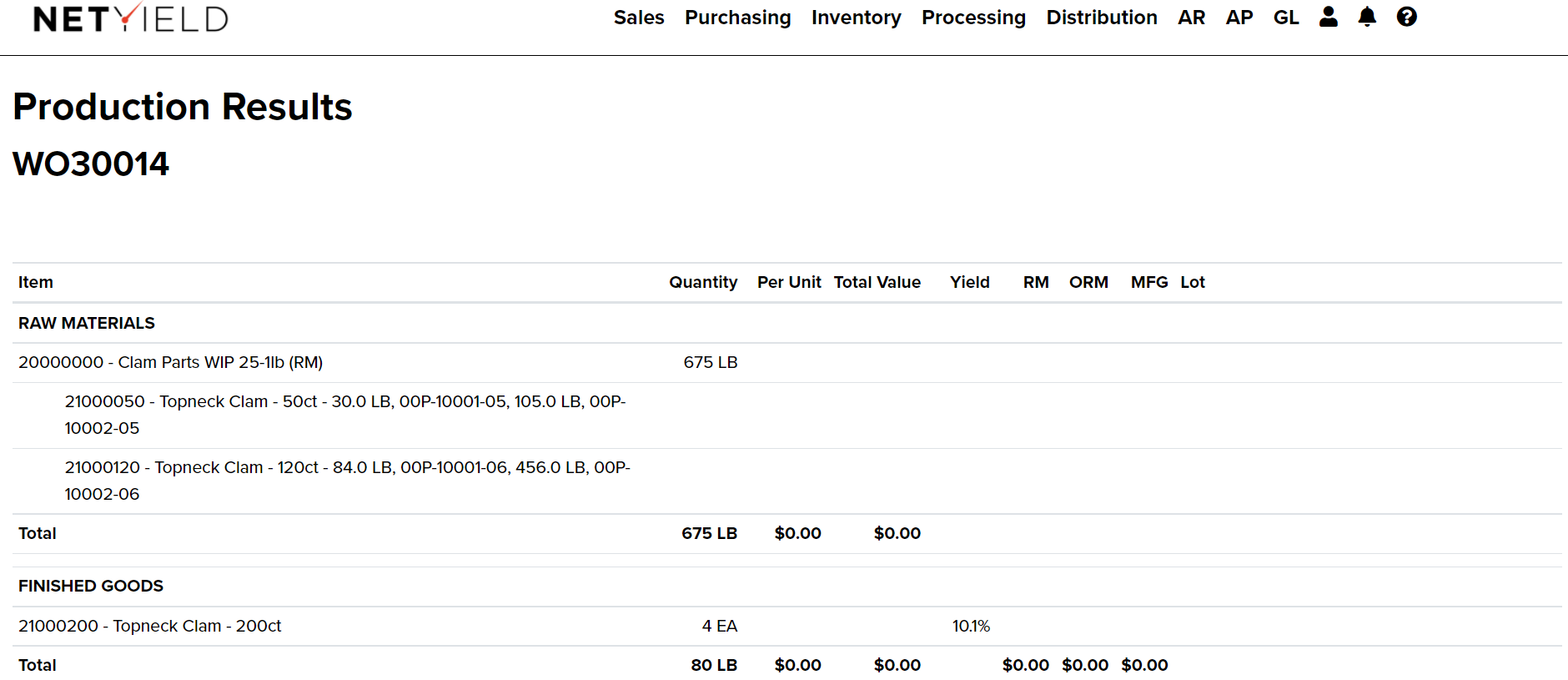

PULLTHROUGH

Automatically generates a transfer ahead of a work order to consolidate multiple item codes into a WIP code

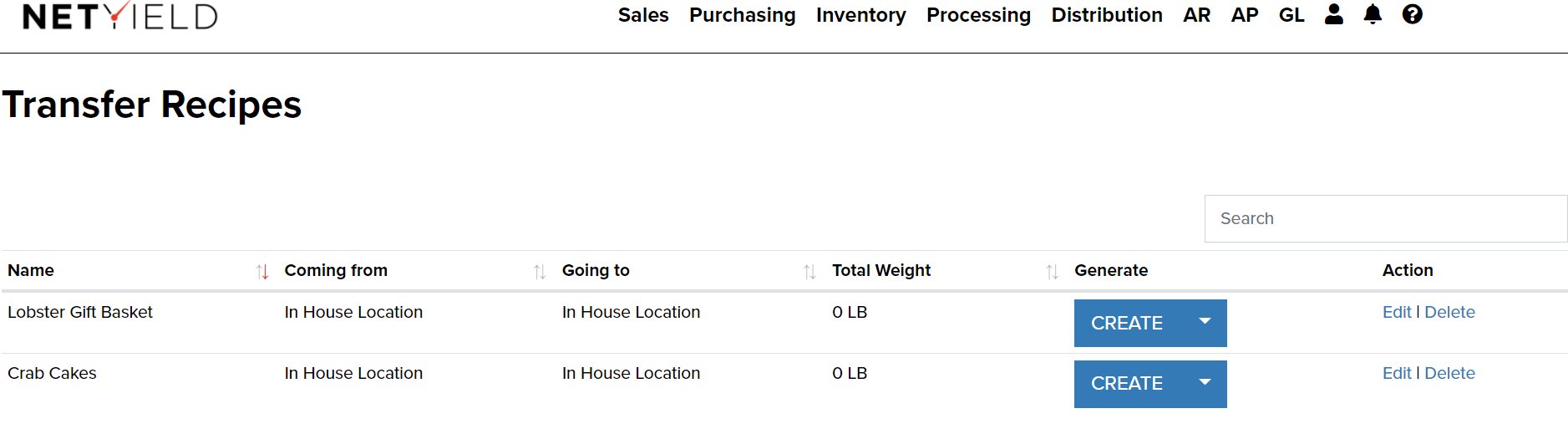

RECIPES

Discrete Bill of Material (many raw materials make one finished good)

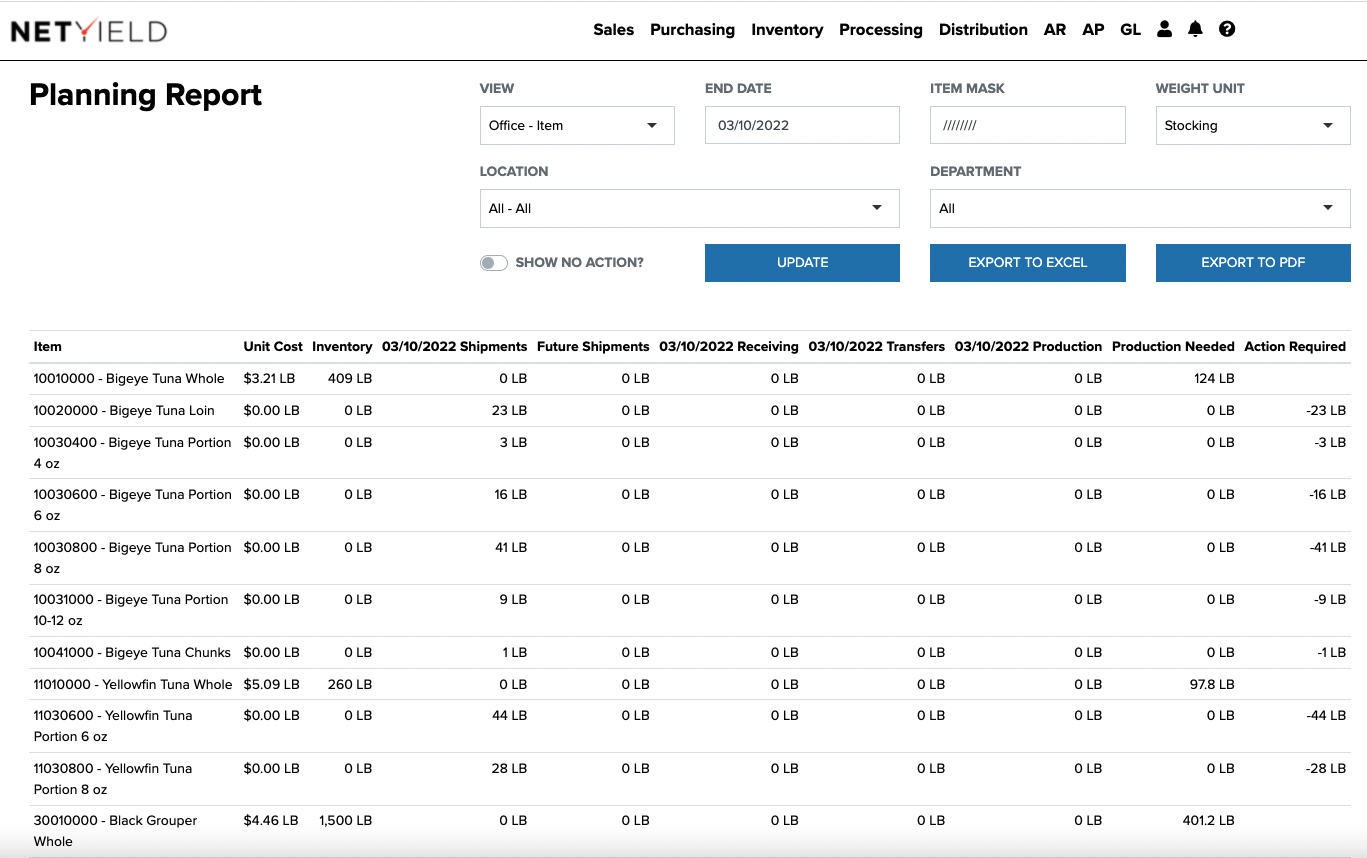

PLANNING REPORTING AND WORK ORDERS

Compare Inventory, Demand, Incoming, Production Demand, Shortages to make a plan; commit raw material and target finished goods for tomorrow’s production